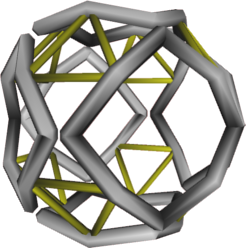

Billy Catringer wrote:A structure like this could be built, but there are several problems with it.

1) How do you wind the coils? If winding coils in this shape is not possible, can a Bitter Plate type of magnet be made in this shape?

I could wind either a standard strand OR quasi-bitter plate magnet in this shape... in copper, and winding with AMSC Gen2 wire would be possible, but a LOT tougher. But assuring appropriate slack or tension to pre-adjust for shrinkage would be much more difficult.

2) Assuming one or the other such cores can be made, how do we support it against the stresses that will be applied to it. We want those brittle cores in compression, not tension, shear or torsion.

If you want them in compression (I suspect you mean you want to squeeze the wires, not push on them) then you would have to transfer the outward loads into a trough which would handle it in tension.

3) The strands of the SC core contract along their lengths more than they contract in any other direction as they chill. This will put a lot of stress on the strands of the winding no matter what the shape of the core and this shape will likely cause them to develp stresses unevenly.

Actually this may be a good thing because it should be easier to wind with a bit of slack than wind with a controlled extra taughtness.

4) It's necessary to pump lots and lots of cooling water through two separate jackets to keep the heat from reaching the superconducting core. The more twists and turns there are in the way of the water, the more friction there is and there will be an increase in the tendency for the structural system to vibrate. Even without the kinks shown in this sketch, the flow of water will be impeded by the additional turns it will have to make. Vibration is going to be hard to avoid with the simpler toroii.

Simple engineering ....ha ha ha ha ha ha ha ha

Personally, I kind of like the idea of using NaK for the first loop. Much lower pressures to deal with at the anticipated temperature. I keep looking for a two phase material that could use the melting process to improve cooling, but...

As far as I can tell, and someone correct me if I am wrong, the SC core will be brittle at LHe temperatures. That means that the support of the SC cores must be as firm and rigid as the foundation of a masonry building. If the structure deforms even a little, the cores will crack or spall and that would lead to a complete failure under load, or the danged things will break sometime during cool down. The entire system will shrink while the two inner coolant loops are filled with LHe and LN2.

Simple engineering ....he he he he ha ha ha