Posted: Sat Nov 05, 2011 12:07 pm

The moderator thanks you.Aslan wrote:I apologize.Betruger wrote:Maybe we could take the politics of this topic out into a separate forum thread.

a discussion forum for Polywell fusion

https://talk-polywell.org/bb/

The moderator thanks you.Aslan wrote:I apologize.Betruger wrote:Maybe we could take the politics of this topic out into a separate forum thread.

Betruger, it is my politics forum. Please visit it.Betruger wrote:Maybe we could take the politics of this topic out into a separate forum thread.

Aslan,Aslan wrote:First, large scale Polywell is proton-Boron fusion reactor that is not suitable to produce neutrons because of first wall lifetime.choff wrote: After I saw the front page of the National Post today I take back the joke. Things are getting paranoid enough right now. Your Polywell effort is probably safe, unless somebody decides it can be used as a neutron source to enrich weapons grade material. Then it gets on the target list, unless Mossad decides to use assasinations instead of bombing. If thats the case, the top researchers have to keep checking the rear view mirror while driving for two guys on a motorbike.

Secondly, the fission research reactors with high neutron production rate are available in every country. If they wanted to make or upgrade their weapons, they had done until now. So they never want.

It seems the real terrorists are those who kill or threaten researchers. The measures that Mossad does, can be easily understood that who are the terrorists?

Yes, I agree, it would need to be a ground up design for the grids, not something to add later.vahid wrote:Yes, I read about multi-grid IECF that increases NPR.ladajo wrote:Also, have you read the Phd papers by Thomas Mcguire or Ryan Meyer

In IECF devices adding "cooling system+multigrid" is very difficult.

ladajo,ladajo wrote:Vahid,

Have you seen this paper?

http://en.scientificcommons.org/18512075

might be easier to pull from here:

http://www.askmar.com/Fusion_files/EMC2 ... e-guns.pdf

edit: added second link

Really, I don't know. We will have some publications before improving.ladajo wrote:You are welcome.

When do you think you will move forward on your next step, (I assume Ion guns)? Or will you think to improve the e-guns first?

Really? I must have misseed such questions. Link please?Netmaker wrote:There were some questions raised about how the design suggestions Kiteman made might be produced.

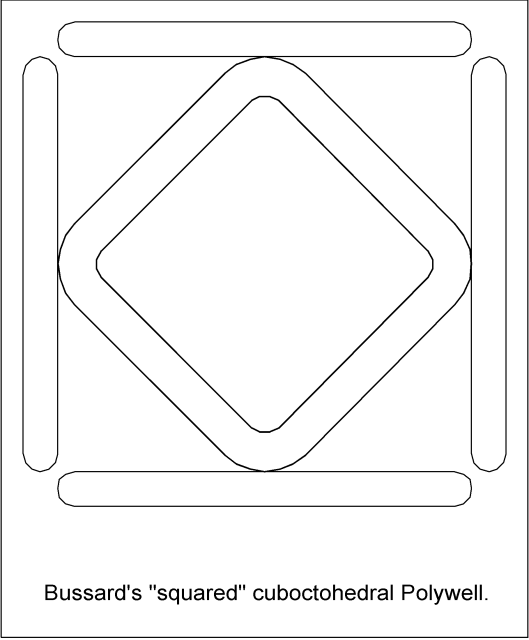

KitemanSA wrote:This is a poor graphic of what Dr. B was planning to do.vahid wrote:Hi, Kiteman,KitemanSA wrote:The first thing that Dr. B. wanted to do after the more robust WB6 (that got called WB7) was to try a square plan-form version of WB6/7. I personally think that it would be beneficial to make it a bowed square plan-form version. And it should be quite easy to build.

PM me if you are intersted in discussion this.

In larger reactors, I think that we have two methods in square-shaped Magrids:

1 - Two adjacent square, the sides are not parallel. (The corners of squares are adjacent.)

2 - Two adjacent square, the sides are parallel. ( The sides of squares, are adjacent.)

In the first case, the cusp can be larger. This is not good.

the magnets would be connected together, prehaps at the corners or perhaps better away from the corners. Since there is no line like cusp, it seems this makes the smallest set of cusps of any of his designes except maybe the dodecahedral unit. I think a bowed version of this would be the place to start.This iw what tombo drew up under my coaching.vahid wrote:

In the second case, non-parallel current carrying wires repel each other. In a real-size Polywell reactor, maybe we can't keep togther, two wires carrying high direct currents. Maybe it is impossible. (40000turns*100Ampers== 4 Mega Amper)

..

If you mean another shape, please send it.

.

This is Dr. B's MPG machine.

This is my bowed version of same.

The corners would need to be connected as stated above.

These next four are different views of a varient of the bowed unit. This is the most difficult to make, but not too hard I think.

Both are on the 3rd page of this thread if you wish to refresh yourself about the full context.vahid wrote:Thank You, kiteman.

The first shape isn't good because of cusps increasing.

Other 6 shapes are very suitable with very small cusps.

Your ideas are very good.

It seems, construction of it will be more difficult.

Do you have some suggestions about constructing them?

My pardon, I thought you meant some actual statement of difficulty, not just a "looks MORE difficult" type of off-hand observation. Yes, they will be MORE difficult to build than a WB6 type machine. That does not imply it is TOO difficult.To which, in reply I wrote:The first one is Dr. Bussard's design and he seemed to think that the cusps would DEcrease and the sphericity would improve such that the overall output would gain by a factor of ~5. It is also by far the easiest of the three to build.vahid wrote: Thank You, kiteman.

The first shape isn't good because of cusps increasing.Yes, but not for free. Co-mention in the patent would be plausible payment.vahid wrote:

Other 6 shapes are very suitable with very small cusps.

Your ideas are very good.

It seems, construction of it will be more difficult.

Do you have some Suggestions about constructing them?