You mistook my meaning - boilers have lots of empty space and are lined with bricks. And yet they withstand shocks.KitemanSA wrote:You are surprised? You, an ex-navy nuke? Why? Every nuke ship in the navy has a boiler. They call it a steam generator, but it is a boiler.MSimon wrote: Boilers on warships?

http://en.wikipedia.org/wiki/Pressurize ... tor#Design

Magrid Vs electrically biased grid

Engineering is the art of making what you want from what you can get at a profit.

Now that I would like to see!

Kite: I have never been fond of the "design" ratings...casual percentages tossed around by paper weanies, like "50% equipment and personnel failures..." it has always made me wonder just what exactly THEY think that means in real terms. I know what it means on the pointy end of the stick.

For the record: the navy still operates boilers (and steam generators).

Kite: I have never been fond of the "design" ratings...casual percentages tossed around by paper weanies, like "50% equipment and personnel failures..." it has always made me wonder just what exactly THEY think that means in real terms. I know what it means on the pointy end of the stick.

For the record: the navy still operates boilers (and steam generators).

Granted, and if the coils were back against the structural casing and intricately integrated into ship structure like the bricks are, I would be sanguine about them too. But standing proud on fairly long cantilevers... no so much.MSimon wrote: You mistook my meaning - boilers have lots of empty space and are lined with bricks. And yet they withstand shocks.

Last edited by KitemanSA on Sat Jul 31, 2010 2:35 am, edited 2 times in total.

The standoff supports may be cantelevers by themselves. But there will be (probably) four of them supporting each magnet. Say it is ~ 2 meters long, If the magnet miner diameter casing is ~ 15-20% of the total (of say, 3 meters) the cantelever standoff could be up to ~ 1/2 meter wide. That is a lot of volume for structure within the casing. There could even be internal trusses. Also, the four standoffs/ cantelevers will be ridgedly supported by the wall, but also it will be supported in compression by the magnet casing being pushed out by the other magnets ( and plasma pressure). Also, in a sinse, at least while operating,the Polywell would act somewhat like a shock absorbing/ magnetic bearing coupling from one side of the wall to the other 5 corresponding sides. I imagine it could be a very strong assembly, yet have some flexability due to the 'magnetic buffers/ bearings.

Also, the mountings for the guns, direct conversion grids, etc. might be designed to give some truss like support to the cantelevers, at least in the regions near the vacuum vessel walls.

Dan Tibbets

Also, the mountings for the guns, direct conversion grids, etc. might be designed to give some truss like support to the cantelevers, at least in the regions near the vacuum vessel walls.

Dan Tibbets

To error is human... and I'm very human.

D Tibbets wrote: Also, the four standoffs/ cantelevers will be ridgedly supported by the wall,

MIL-S-901D states:

"6.4 General information. The following information is provided as guidance for designers and others responsible for fulfilling the provisions of this specification:

(a) All items will exhibit some deflection during exposure to shock; nothing is “rigid” , except in a relative sense."

And they mean it!

I once watched a 500KW Motor-Generator "flex" and toss a guy across the room who was leaning on it at the time. It had been paralleled 120 degrees out of phase. I am just glad I had chosen something different to lean on while we were talking. The impressive part is that the mounts survived. Somebody got something right in the design phase, but probably for a different reason, I do not think they anticipated that type of transient source, but were thinking about external loading.

Apply enough force, it will move. Interesting for me, while thinking over this thread regarding cyclic and pulse loading on the polywell, I can't help but draw mental comparisons for Johann's discussion in the other thread on how energy moves in my mind's eye.

Apply enough force, it will move. Interesting for me, while thinking over this thread regarding cyclic and pulse loading on the polywell, I can't help but draw mental comparisons for Johann's discussion in the other thread on how energy moves in my mind's eye.

We had a 500 MVA Westinghouse generator connect to the system 120 degrees out of phase from a sync check relay failure when the operator was putting the unit on line. Made a real mess, turbine to generator coupling bolts sheared, a couple of generator coils failed, end turn blocking all busted up. Not pretty, scared the operators for some reason.

When real power is being handled, things can get exciting.

When real power is being handled, things can get exciting.

Counting the days to commercial fusion. It is not that long now.

Of course nothing is absolutely ridged. But the polywell supported from all 6 walls allows for a lot of cross bracing. The magnetic buffering between the magnets also adds some buffering for shocks. How would supporting the entire magrid assembly from only one side handle shocks and whiplash forces? With nubs between the magnets there is some support at that level, but even with this, when the magnets are 2-3 meters in diameter, there would be a lot of force applied to these small nubs. I'm no engineer, so I may be way off, but it seams to me that much stronger supports could be built (and shielded) when all sides are directly linked to the presumably very strong vacuum vessel wall. Since this also apparently improves performance, it seems like a win- win situation.

Also, keep in mind that there will be a lot of things outside the magrid anyway. Guns, possibly direct conversion grids, etc. The magrid to wall supports surround each cusp so they are convenient for attaching the various converters etc. Otherwise, these would only have support from the vacuum vessel walls to resist shocks (or shell like assemblages supported from only the single side standoffs that supports the nub connected magrid).

I'm guessing the strongest support would be with standoffs all around. If the magnetic buffering between the separate magnets is not sufficient, nubs could be added with an accepted decrease in efficiency.

Dan Tibbets

Also, keep in mind that there will be a lot of things outside the magrid anyway. Guns, possibly direct conversion grids, etc. The magrid to wall supports surround each cusp so they are convenient for attaching the various converters etc. Otherwise, these would only have support from the vacuum vessel walls to resist shocks (or shell like assemblages supported from only the single side standoffs that supports the nub connected magrid).

I'm guessing the strongest support would be with standoffs all around. If the magnetic buffering between the separate magnets is not sufficient, nubs could be added with an accepted decrease in efficiency.

Dan Tibbets

To error is human... and I'm very human.

By "swinging in the breeze" so to speak.D Tibbets wrote: Of course nothing is absolutely ridged. But the polywell supported from all 6 walls allows for a lot of cross bracing. The magnetic buffering between the magnets also adds some buffering for shocks. How would supporting the entire magrid assembly from only one side handle shocks and whiplash forces?

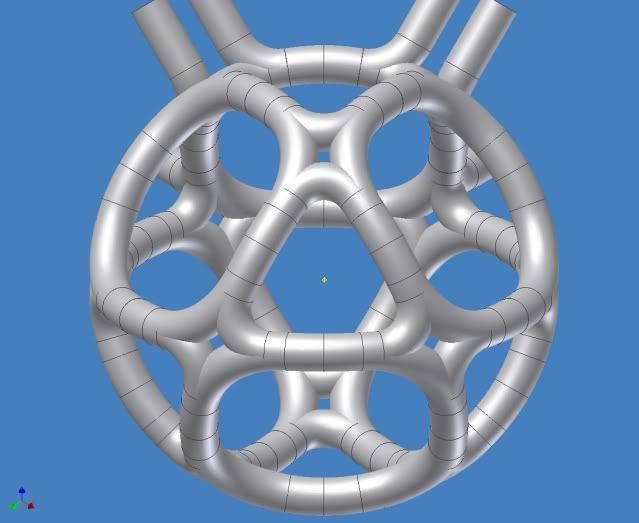

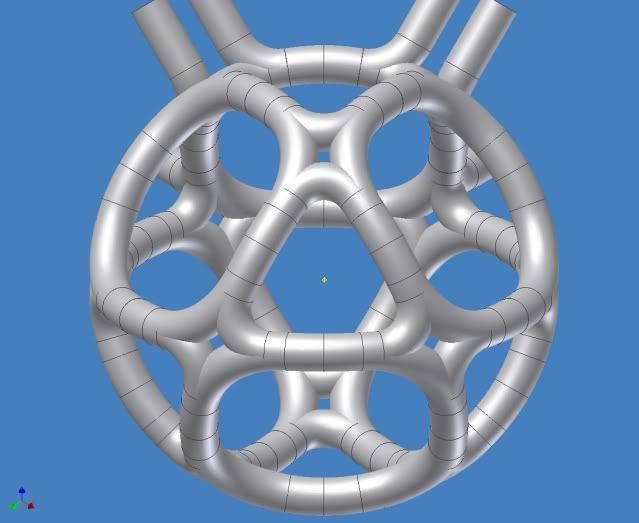

Actually, I don't like the "nubs" design either! I proposed alterations to it several years ago. I finally got someone (Tombo) to develop a great drawing of approximately what I wanted (then left it well enough alone and gave thanks that he did this much, THANK YOU VERY MUCH Tombo!!!). This is it.D Tibbets wrote:With nubs between the magnets there is some support at that level, but even with this, when the magnets are 2-3 meters in diameter, there would be a lot of force applied to these small nubs. I'm no engineer, so I may be way off, but it seams to me that much stronger supports could be built (and shielded) when all sides are directly linked to the presumably very strong vacuum vessel wall.

Beautiful, isn't it? THIS is very much like the monocoque MaGrid I would like to see. (The only improvement would be to tinker with the legs a bit as I don't think they need to be that big nor that many. A total of 4 thinner ones would probably do just fine.

If this hung from the top of the chamber, that chamber wall could perform as an excellent spring against shock while not seeing ANY load from the magnets which would be self contained within the MaGrid. Further more, the total amount of material that was not protected by said magnet would be as small as possible; a win, win, win situation.D Tibbets wrote:Since this also apparently improves performance, it seems like a win- win situation.

essentially AT the shell so no cantilevel...D Tibbets wrote: Also, keep in mind that there will be a lot of things outside the magrid anyway. Guns,

which would nicely be attached to the shell as a cage like structure, not needing or benefitting much from a forest of legs between them and the MaGrid...D Tibbets wrote:possibly direct conversion grids,

IBIDD Tibbets wrote:etc. The magrid to wall supports surround each cusp so they are convenient for attaching the various converters etc.

IBID againD Tibbets wrote:Otherwise, these would only have support from the vacuum vessel walls to resist shocks (or shell like assemblages supported from only the single side standoffs that supports the nub connected magrid).

Use the monocoque MaGrid above and you don't need that forest of supports nor any "nubs" reducing efficiency.D Tibbets wrote: I'm guessing the strongest support would be with standoffs all around. If the magnetic buffering between the separate magnets is not sufficient, nubs could be added with an accepted decrease in efficiency.

You really, really don't want to do that.KitemanSA wrote:Actually, I don't like the "nubs" design either! I proposed alterations to it several years ago. I finally got someone (Tombo) to develop a great drawing of approximately what I wanted (then left it well enough alone and gave thanks that he did this much, THANK YOU VERY MUCH Tombo!!!). This is it.

Beautiful, isn't it? THIS is very much like the monocoque MaGrid I would like to see. (The only improvement would be to tinker with the legs a bit as I don't think they need to be that big nor that many. A total of 4 thinner ones would probably do just fine.

You can't make it so that you don't get one of two things happening:

A) some of the holes with the magnetic field pointing "out"

or

B) some of the bars with no magnetic field, because you have currents flowing both ways

Either one of these will be very, very bad.

A) will lead to huge losses, as the electrons and ions follow the magnetic fields right out of containment

B) will lead to huge numbers of electrons grounding themselves on the gird.

Wandering Kernel of Happiness

Sorry, you are incorrect. This MaGrid will work just fine. The "square plan form" are the ins and the triangulars are the outs. The little ones are the "X cusps" a.k.a funny cusps and have null fields per Dr. Bussard's original patent.WizWom wrote: You really, really don't want to do that.

You can't make it so that you don't get one of two things happening:

A) some of the holes with the magnetic field pointing "out"

or

B) some of the bars with no magnetic field, because you have currents flowing both ways

Either one of these will be very, very bad.

A) will lead to huge losses, as the electrons and ions follow the magnetic fields right out of containment

B) will lead to huge numbers of electrons grounding themselves on the gird.

All current thru any tube flows the same way.

This is a variation on the MPG which also worked well.

Only the legs might be outside the magnetic protection but there are many fewer of them than the forest proposed for the chamber mounted coil arrangement.

At first I didn't see how the wires could be wound continuously in the proper orientations, but I'll concede that it looks like it is possible. The problem I see with this arangement is that the small open squares would present a small 'diamond shaped' cusp. This is small but the cusps lead into the corners where the windings split. This would be a direct path to the magnet casings at those points. I visualize it as the same as having conventional nubs between magnets except these would be square with a hole in them. Perhaps the exposed surface area would be smaller (good) but not absent. Essentially you have four cusps lines intercepting the metal at each 'nub ' instead of the two (linear or funny cusp coming in from either side) in the classic (WB 6) design.. I supose that the amount of lateral transport in the magnetic fields would be important. If the se modified nub losses are not greater (or hopefully smaller) than the classic nubs (assuming they are also magnetically shielded), then the greater sphericity of this design should give some benifit (?).

As mentioned though this increases the path any coolant would take through the complex of tubes, so cooling would require substantially greater flows and or volumes of coolant. It is less challenging to cool each coil separately. I'm not sure how the plumbing would be arranged to assure even coolant flow through all of the branches.

[EDIT]

In the patent application, it is hinted that if the cusp loss surfaces can be minimized the recirculation efficiency may approach the efficiency of cross field transport for electron losses. If that is the case, having more magnetically shielded surfaces in the machine (like in this design) may be a penalty. There are a lot of interrelated considerations in optimizing the physics and the engineering of the system.

And, even with the basic WB 6 configuration, the fusion output scales so fast, that it may be the size, with the associated thermal wall loading, that is the limiting factor. ie: increased efficiency might allow a smaller size for a given power out, but if the thermal loads cannot be handled at that smaller size, nothing is gained. This would apply especially to D-D fusion. P-B11 fusion might require all of the optimizations possible in order to work. .

Dan Tibbets

As mentioned though this increases the path any coolant would take through the complex of tubes, so cooling would require substantially greater flows and or volumes of coolant. It is less challenging to cool each coil separately. I'm not sure how the plumbing would be arranged to assure even coolant flow through all of the branches.

[EDIT]

In the patent application, it is hinted that if the cusp loss surfaces can be minimized the recirculation efficiency may approach the efficiency of cross field transport for electron losses. If that is the case, having more magnetically shielded surfaces in the machine (like in this design) may be a penalty. There are a lot of interrelated considerations in optimizing the physics and the engineering of the system.

And, even with the basic WB 6 configuration, the fusion output scales so fast, that it may be the size, with the associated thermal wall loading, that is the limiting factor. ie: increased efficiency might allow a smaller size for a given power out, but if the thermal loads cannot be handled at that smaller size, nothing is gained. This would apply especially to D-D fusion. P-B11 fusion might require all of the optimizations possible in order to work. .

Dan Tibbets

Last edited by D Tibbets on Sun Aug 01, 2010 9:21 pm, edited 1 time in total.

To error is human... and I'm very human.

As you point out, if the electrons can turn a corner instantaneously in a zero electrical field hole in the magnetic field, it can reach the casing. But since there is no NET electrical gradient, why would it? Remember, this hole is positive ALL around, so no NET electric pull. The field doesn't show up until the electron EXITS the hole.D Tibbets wrote:At first I didn't see how the wires could be wound continuously in the proper orientations, but I'll concede that it looks like it is possible. The problem I see with this arangement is that the small open squares would present a small 'diamond shaped' cusp. This is small but the cusps lead into the corners where the windings split. This would be a direct path to the magnet casings at those points. I visualize it as the same as having conventional nubs between magnets except these would be square with a hole in them. Perhaps the exposed surface area would be smaller (good) but not absent. Essentially you have four cusps lines intercepting the metal at each 'nub ' instead of the two (linear or funny cusp coming in from either side) in the classic (WB 6) design.. I supose that the amount of lateral transport in the magnetic fields would be important. If the se modified nub losses are not greater (or hopefully smaller) than the classic nubs (assuming they are also magnetically shielded), then the greater sphericity of this design should give some benifit (?).

As mentioned though this increases the path any coolant would take through the complex of tubes, so cooling would require substantially greater flows and or volumes of coolant. It is less challenging to cool each coil separately. I'm not sure how the plumbing would be arranged to assure even coolant flow through all of the branches.

This item, as I currently have it envisioned, is a stack of MPG type windings. Each stack has one "in" and one "out" for the coolant and it flows thru like the MPG, or approximately like that. Simple really.